On this page:

New nano-material for self-powered electronics

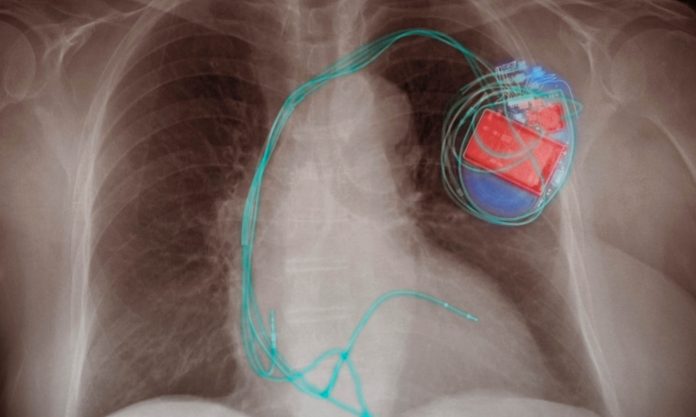

A new type of ultra-efficient, nano-thin material could advance self-powered electronics, The flexible and printable material, which can convert mechanical pressure into electrical energy, has been developed by an Australian research team led by RMIT University and assisted by the Australian National Fabrication Facility, Microscopy Australia, National computational infrastructure and Pawsey supercomputing centre. The material’s potential medical applications include internal sensors and self-powering biotechnologies, such as devices that convert blood pressure into a power source for pacemakers.

Image Credit: RMIT University

More information available

New antibiotic drugs against resistant bacteria

Multi-drug resistant bacteria are a great danger to public health. Researchers have recently developed a new antibiotic using Phenomics Australia’s Histopathology and Slide Scanning Service. The breakthrough is part of a study to find new-generation antibiotics. The new drug targets multi-drug resistant bacteria and is currently in a clinical trial.

More information available

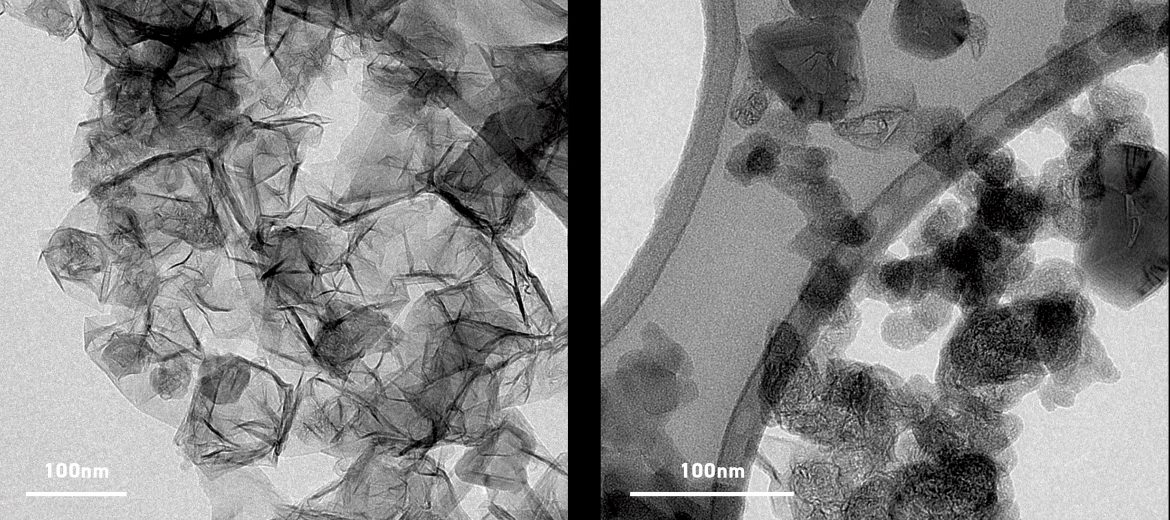

Enabling manufacturing processes

Brisbane based tech company; Graphene Manufacturing Group (GMG) have developed their manufacturing process with the help of Microscopy Australia. Using innovative techniques, Microscopy Australia can model the graphene that is being produced. GMG are then able to adjust their manufacturing process to suit their customer. Graphene is the strongest material ever tested and it conducts electricity. It has applications across many industries.

More information available

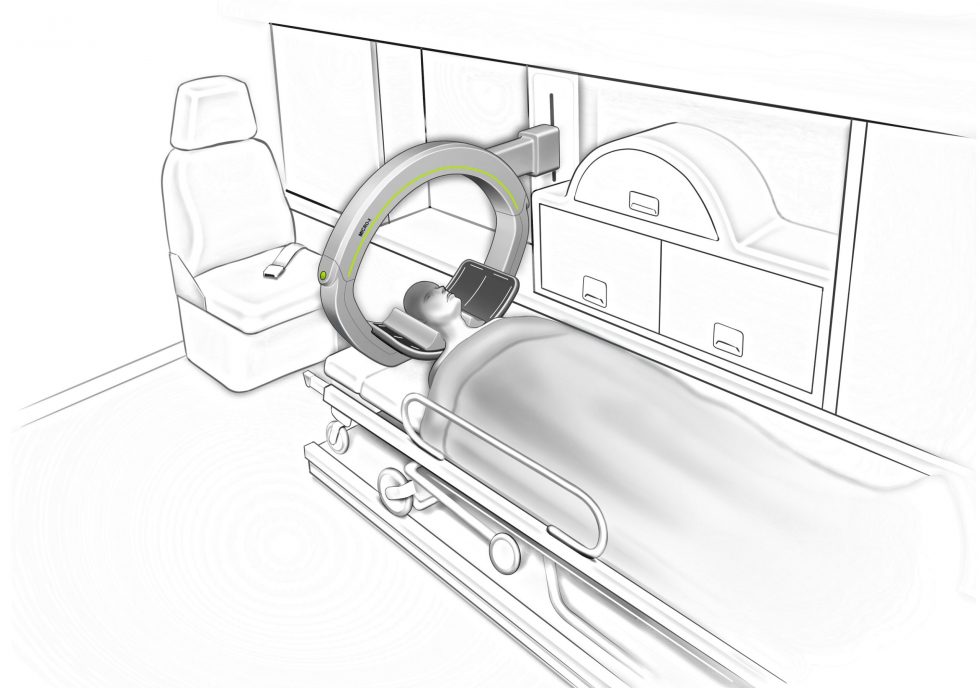

Department of Health backs game changing portable CT scanner by Micro-X

The Australian National Fabrication Facility (ANFF) has developed ground-breaking technology with Australian manufacturing company Micro X. Their new carbon nanotube (CNT) emitter technology is at the foundation of new age portable brain scanners. The new design is much smaller, allowing portable brain scanners to be installed in ambulances. The application in the field will increase the ability of medical staff to diagnose and treat strokes.

More information available

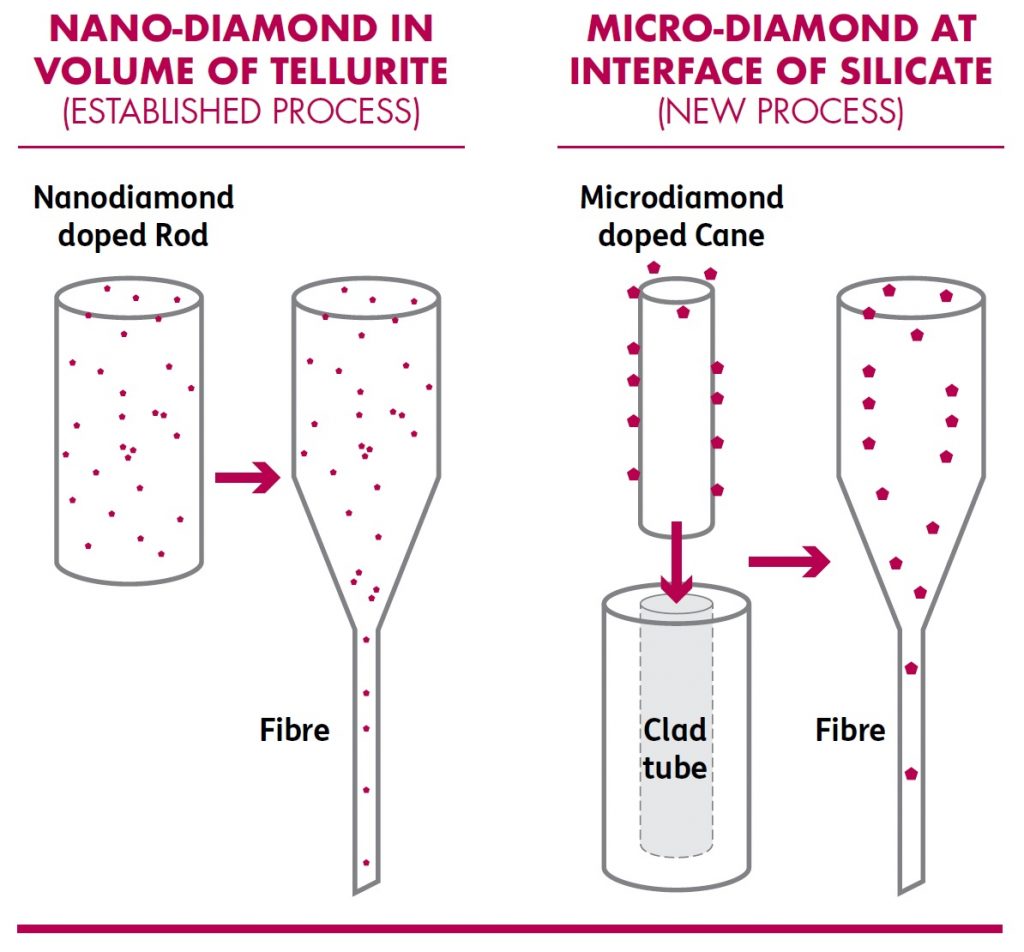

Diamond encrusted sensors

A group of researchers have been working with the Australian National Fabrication Facility to manufacture optical fibres embedded with diamonds. Researchers had been unsuccessful for a decade until an artist from Adelaide provided them with a lightbulb moment. Her technique to spread diamond throughout silicate glass inspired what is now known as interface doping. The diamonds being used contain nitrogen vacant centres which are very useful in testing magnetic fields.

More information available

Deuteration may lead to better sunscreens

The National Deuteration Facility has been exploring research opportunities in the personal care industry. Deuteration has proven to be an effective way of enhancing material properties. Sunscreen for example has some unstable components that may be stabilised using deuteration to increase shelf life. The results from this research could have a great impact on preventing skin cancer.